The company is the earliest enterprise to design and manufacture wind-energy gearboxes, once took part in the Key Science and Technology Projects of National Ninth Five Plan, Research on Key Technology of Large Wind Power Generation System, drafted national standard GB/T19073-2008 Wind Turbine Generator System Gearbox. The company may provide wind turbine gearboxes ranging 100kW~5.5kW. The products over 1.5MW obtain internationally advanced core technologies of differential and flexible pin, featuring in even in load distribution, high in reliability, large in power density; suitable for working conditions on ocean and plateau. Sorts of wind turbine gearboxes the company produced have been operated in large wind farm in the country. Design and manufacturing capability are in domestic leading level.

Wind Turbine Gearbox below 1MW

Wind turbine gearbox below 1MW, mostly applies parallel shaft or planetary gearing transmission; using gears made of quality steel alloy, in which external gears reaching class 5 (ISO1328) in precision and internal gears class 6 (ISO1328); carrying out dynamic simulation analysis with on gears with simulation software to get best profile effect; conducting FEM analysis on housing, torsion arm, planet carrier to optimize the structure under the precondition of ensuring strength and stiffness; providing forced lubrication to bearings to prolong bearing service life.

1.5MW Series Wind Turbine Gearbox

1.5MW series wind turbine gearbox is designed of planets + parallel shaft gearing structure, using power split arrangement and flexible pin technology, thus making gearbox compact in structure, high in reliability, duration in service life; applying gears made of quality alloy steel, in which external gears reaching class 5 (ISO1328) in precision and internal gears class 6 (ISO1328); carrying out dynamic simulation analysis with on gears with simulation software to get best profile effect; conducting FEM analysis on housing, torsion arm, planet carrier to optimize the structure under the precondition of ensuring strength and stiffness; providing forced lubrication to gears and bearings to ensuring gearbox service life.

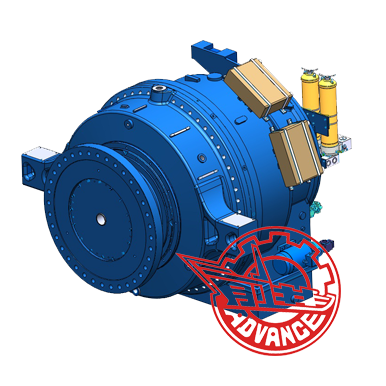

2MW Series Wind Turbine Gearbox

2MW series wind turbine gearbox is designed of planets + parallel shaft gearing structure, using power split arrangement and flexible pin technology, thus making gearbox compact in structure, high in reliability, duration in service life; on request, input and output being optional to be identical or contrary in direction; applying gears made of quality alloy steel, in which external gears reaching class 5 (ISO1328) in precision and internal gears class 6 (ISO1328); carrying out dynamic simulation analysis with on gears with simulation software to get best profile effect; conducting FEM analysis on housing, torsion arm, planet carrier to optimize the structure under the precondition of ensuring strength and stiffness; providing forced lubrication to gears and bearings to ensuring gearbox service life.

2.5MW Series Wind Turbine Gearbox

2.5MW series wind turbine gearbox is designed of planets + parallel shaft gearing structure, using power split arrangement and flexible pin technology, thus making gearbox compact in structure, high in reliability, duration in service life; applying gears made of quality alloy steel, in which external gears reaching class 5 (ISO1328) in precision and internal gears class 6 (ISO1328); carrying out dynamic simulation analysis with on gears with simulation software to get best profile effect; conducting FEM analysis on housing, torsion arm, planet carrier to optimize the structure under the precondition of ensuring strength and stiffness; providing forced lubrication to gears and bearings to ensuring gearbox service life.

3MW Series Wind Turbine Gearbox

3MW series wind turbine gearbox is designed of planets + parallel shaft gearing structure, using power split arrangement and flexible pin technology, thus making gearbox compact in structure, high in reliability, duration in service life; applying gears made of quality alloy steel, in which external gears reaching class 5 (ISO1328) in precision and internal gears class 6 (ISO1328); carrying out dynamic simulation analysis with on gears with simulation software to get best profile effect; conducting FEM analysis on housing, torsion arm, planet carrier to optimize the structure under the precondition of ensuring strength and stiffness; providing forced lubrication to gears and bearings to ensuring gearbox service life.

3.6MW Series Wind Turbine Gearbox

3.6MW series wind turbine gearbox is designed of planets + parallel shaft gearing structure, using power split arrangement and flexible pin technology, thus making gearbox compact in structure, high in reliability, duration in service life; applying gears made of quality alloy steel, in which external gears reaching class 5 (ISO1328) in precision and internal gears class 6 (ISO1328); carrying out dynamic simulation analysis with on gears with simulation software to get best profile effect; conducting FEM analysis on housing, torsion arm, planet carrier to optimize the structure under the precondition of ensuring strength and stiffness; providing forced lubrication to gears and bearings to ensuring gearbox service life.

5MW Series Wind Turbine Gearbox

5MW series wind turbine gearbox is designed of planets + parallel shaft gearing structure, using power split arrangement and flexible pin technology, thus making gearbox compact in structure, high in reliability, duration in service life; applying gears made of quality alloy steel, in which external gears reaching class 5 (ISO1328) in precision and internal gears class 6 (ISO1328); carrying out dynamic simulation analysis with on gears with simulation software to get best profile effect; conducting FEM analysis on housing, torsion arm, planet carrier to optimize the structure under the precondition of ensuring strength and stiffness; providing forced lubrication to gears and bearings to ensuring gearbox service life.

Yaw and Pitch Gearbox

Yaw and pitch gearbox applies multi-planet arrangement, compact in structure; applying gears made of quality alloy steel, in which external gears reaching class 5 (ISO1328) in precision and internal gears class 6 (ISO1328); using reliable sealing technology to avoid leakage of lubrication oil.